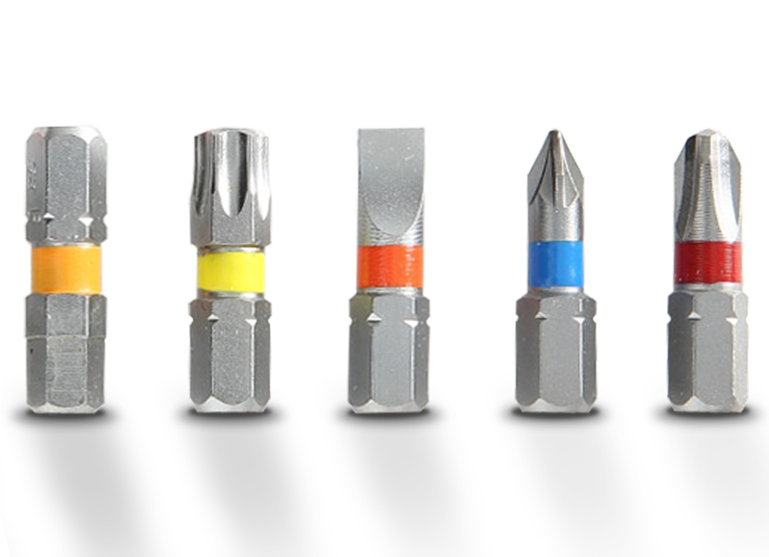

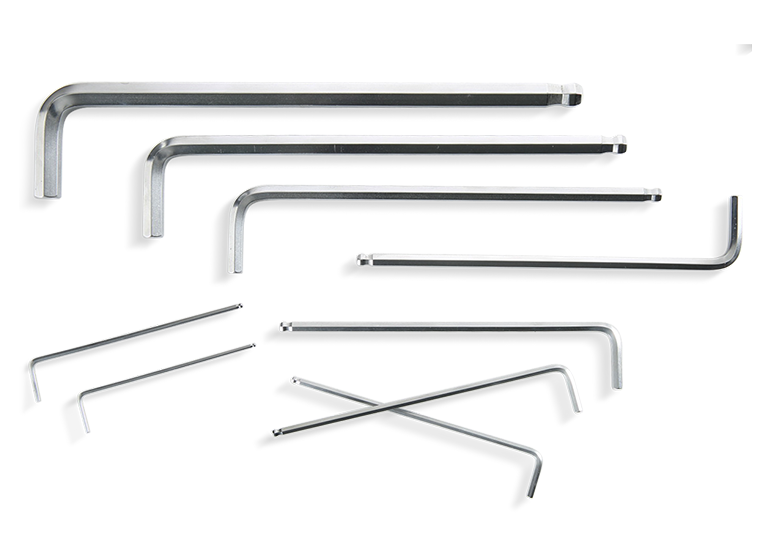

Customized Production Solutions for Hand Tools

Catering to various requirements for hand tools production, Kotung provides one-stop services for hand tools manufacturers. We provide consultation for designing and building the production lines for bits, allen keys, sockets, and screwdrivers. We aim to provide the best equipment and services for making good quality hand tools.

Our customization service goes through the following steps:

- Steel

- Casting parts

- Parts from suppliers

- In-house parts