Product Description

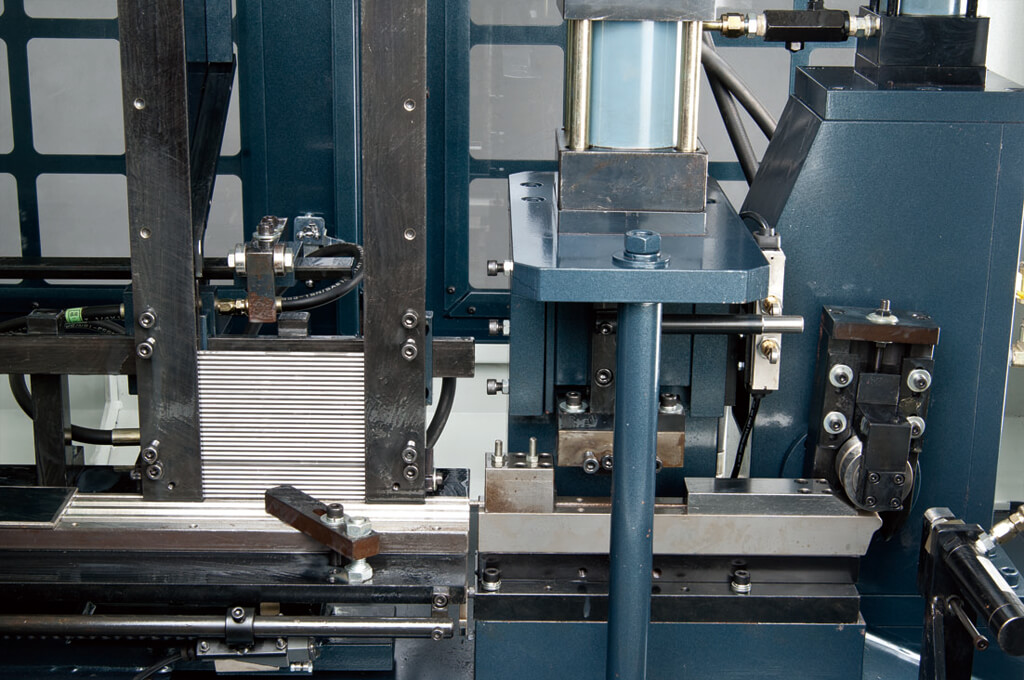

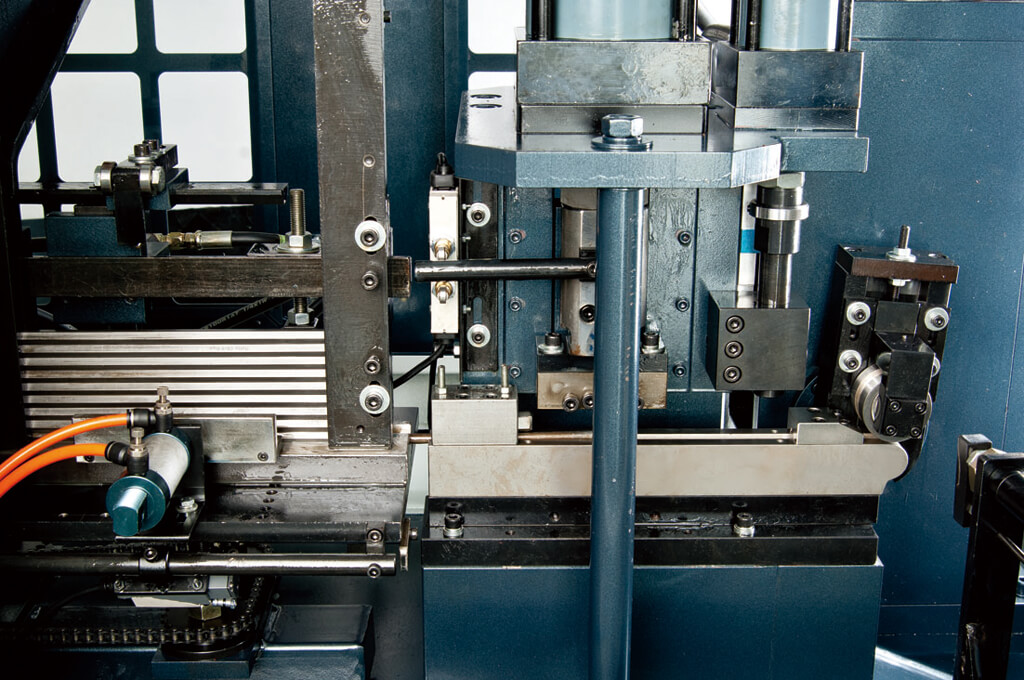

KT-235L/KT-265L/KT-285L Bending Machines

The production principle of Kotung’s bending machine is to apply a full hydraulic system, and cooperate with the precision-made bending angle die to perform bending process.Placing the workpiece steadily on the feeder channel, push forward and hydraulic cylinder press down to fold different bending angle, 90°,95°or 100°.

Stamping process is also of this machine, so it can complete bending and stamping process in one machine.

Most factories use hydraulic punch machine for bending process of L-key, because the punch process is faster and it also carry out high production capacities.However, the punch machine is also dangerous; the operator may cause accident of crushed finger by the punch machine if without fully concentrate.

The punch machine is also hard to control the pressure, and it is easily to cause the brittle fracture of workpiece. Therefore, Kotung’s bending machine has unique advantages in the market; it performs stability and smoothly, it wins highly praised by factory owners.

Product Specifications

| Item/Model | KT-235 L | KT-265 L | KT-285 L |

|---|---|---|---|

| Workpiece Diameter | 1.5 - 3MM | 4 - 8MM | 10 - 14MM |

| Workpiece Length | 80 - 200MM | 80 - 250MM | 110 - 350MM |

| Material Type | Hex /Round | Hex /Round | Hex /Round |

| Collet Chuck | #25 | #25 | #25 |

| Spindle Motor | 2HP | 2HP | 3HP |

| Hydraulic Motor | 1HP | 1HP | 2HP |

| Output (pce / per min) | 8 ~ 15pcs. | 6 - 10PCS | 6 - 8PCS |

| Machine Dimensions | 135x80x205 | 180x110x225 | 180x110x225 |

| New Weight | 480KG | 550KG | 600KG |

Related Products