To modernize screwdriver production, Kotung transforms the traditional machine series and integrates with a computer numerical control system; the first CNC machine model is KT-100.

This KT-100 series combines computerized operating system; it brings machine setting or machining process easier; the operator just edit computer numerical on keyboard to deliver the order for different tasks, unlike the traditional machines have complicate progress for changing parts. CNC machine series also initiates the automatic operation, it can continuously run three shifts for 24 hours, the highly productive and precise quality are the best advantages of KT-100 series.

KT-100 Front Feeding Series can be installed with a vibration bowl or setting material rack inside the machine-working center, push workpiece front in and front out. This is suitable for small dimension and short length workpiece.

KT-100 Rear Feeding Series feature a step feeder system, pushing workpiece rear in and front out and it is suitable for big dimension and long length workpieces. Comparing to traditional magazine material feeding rack, the improved step feeder provides more stable feeding and discharging of raw materials more efficient.

Three models of KT-100 CNC Series

- KT-100CTMR CNC Turning and Milling Rear

- KT-100CTPR CNC Turning and Polygon Rear

- KT-100CTFR CNC Turning and ProFilator Rear

|

|

|

| CTM tooling holder | CTP tooling holder | CTF tooling holder |

| Item/Model | KT-100CTM | KT-100CTF | KT-100CTP | |

|---|---|---|---|---|

| Feeding Type | Front Feeding | Front Feeding | Front Feeding | |

| Machining Capacity | φ25MM/φ32MM | φ25MM/φ32MM | φ25MM/φ32MM | |

| Max. Machining Diameter | 25-65MM | 25-65MM | 25-65MM | |

| Max. Machining Length | 0.001MM | 0.001MM | 0.001MM | |

| Minimum Input Unit | 92MM | 92MM | 92MM | |

| Swing Slide Diameter | ||||

| Cutting Tool | Apply Cutting Tool: | φ16MM/φ20MM | φ16MM/φ20MM | φ16MM/φ20MM |

| Max. Bore Tool: | φ20MM | φ20MM | φ20MM | |

| Spindle | Spindle Nose: | A2-3 | A2-3 | A2-3 |

| Hydraulic Chuck: | 4” | 4” | 4” | |

| Spindle Motor: | 4.5KW | 4.5KW | 4.5KW | |

| Spindle Speed: | 5000RPM | 5000RPM | 5000RPM | |

| Spindle Bore Diameter: | 38MM | 38MM | 38MM | |

| Collet Chuck: | YB25/C32 | YB25/C32 | YB25/C32 | |

| Axis Travel | X-Axis Stroke: | 250MM | 250MM | 250MM |

| Z-Axis Stroke: | 130MM | 130MM | 130MM | |

| X,Z Axis Rapid Speed: | 15M/MIN | 15M/MIN | 15M/MIN | |

| Others | Machine Size(LxWxH): | 150*250*170 | 150*250*170 | 150*250*170 |

| Machine Weight: | 1100KG | 1100KG | 1100KG | |

| Request Power: | AC/3HP/220V/10KW | AC/3HP/220V/10KW | AC/3HP/220V/10KW | |

| Controller: | SYNTEC EZ4-T | SYNTEC EZ4-T | SYNTEC EZ4-T | |

Rear Feeding

| Item/Model | KT-100CTM | KT-100CTF | KT-100CTPR | |

|---|---|---|---|---|

| Feeding Type: | Back Feeding | Back Feeding | Back Feeding | |

| Machining Capacity: | φ19MM/φ24MM | φ19MM/φ24MM | φ19MM/φ24MM | |

| Max. Machining Diameter: | 65-350MM | 65-350MM | 65-350MM | |

| Max. Machining Length: | 0.001MM | 0.001MM | 0.001MM | |

| Minimum Input Unit: | 92MM | 92MM | 92MM | |

| Swing Slide Diameter: | ||||

| Cutting Tool | Cutting Tool: | φ16MM/φ20MM | φ16MM/φ20MM | φ16MM/φ20MM |

| Max. Bore Tool: | φ20MM | φ20MM | φ20MM | |

| Spindle | Spindle Nose: | A2-3 | A2-3 | A2-3 |

| Hydraulic Chuck: | 4” | 4” | 4” | |

| Spindle Motor: | 4.5KW | 4.5KW | 4.5KW | |

| Spindle Speed: | 5000RPM | 5000RPM | 5000RPM | |

| Spindle Bore Diameter: | 38MM | 38MM | 38MM | |

| Collet Chuck: | YB25/C32 | YB25/C32 | YB25/C32 | |

| Axis Travel | X-Axis Stroke: | 250MM | 250MM | 250MM |

| Z-Axis Stroke: | 130MM | 130MM | 130MM | |

| X,Z Axis Rapid Speed: | 15M/MIN | 15M/MIN | 15M/MIN | |

| Others | Machine Size(LxWxH): | 300*125*170 | 300*125*170 | 300*125*170 |

| Machine Weight: | 1400KG | 1400KG | 1400KG | |

| Request Power: | AC/3HP/220V/10KW | AC/3HP/220V/10KW | AC/3HP/220V/10KW | |

| Controller | SYNTEC | SYNTEC | SYNTEC | |

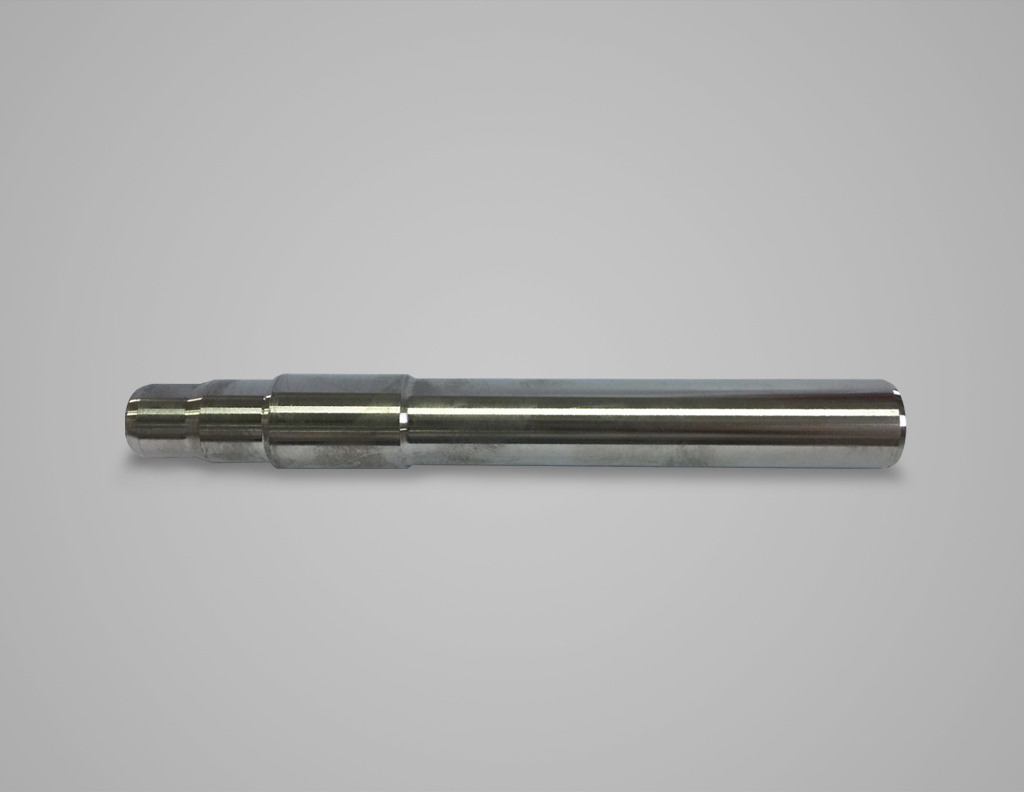

Material Tube

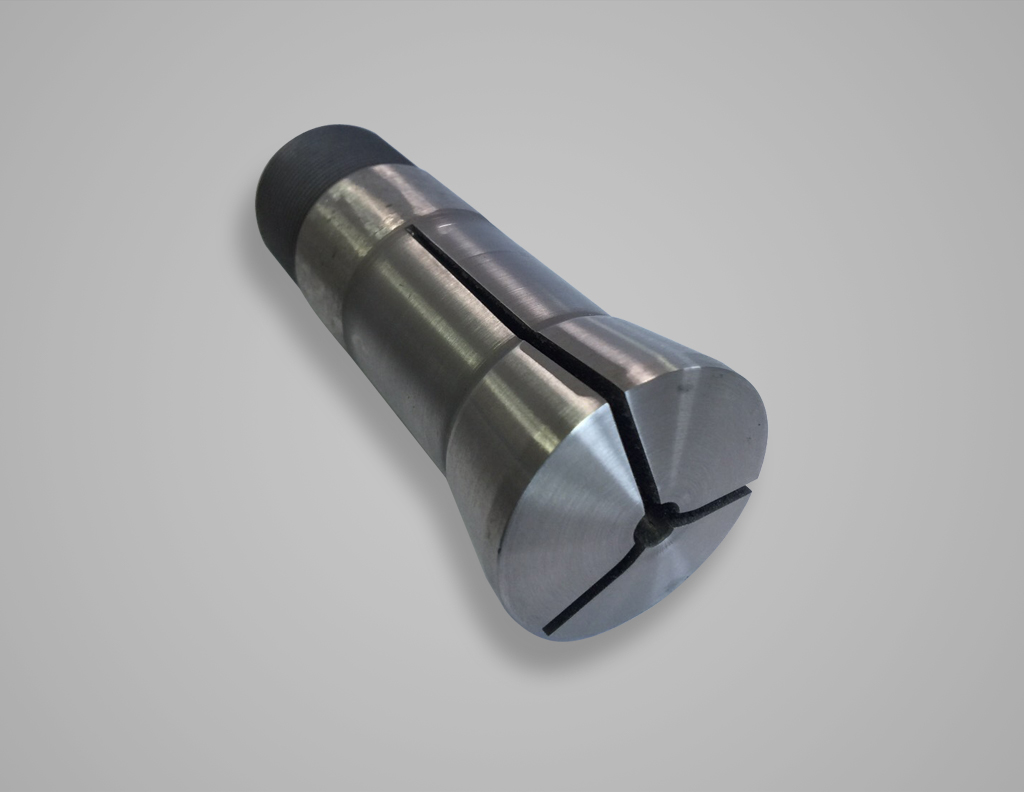

Collet Chuck

Vibration Bowl

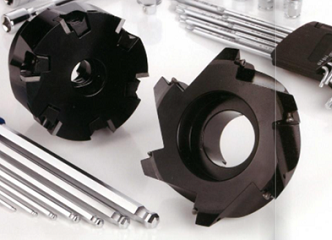

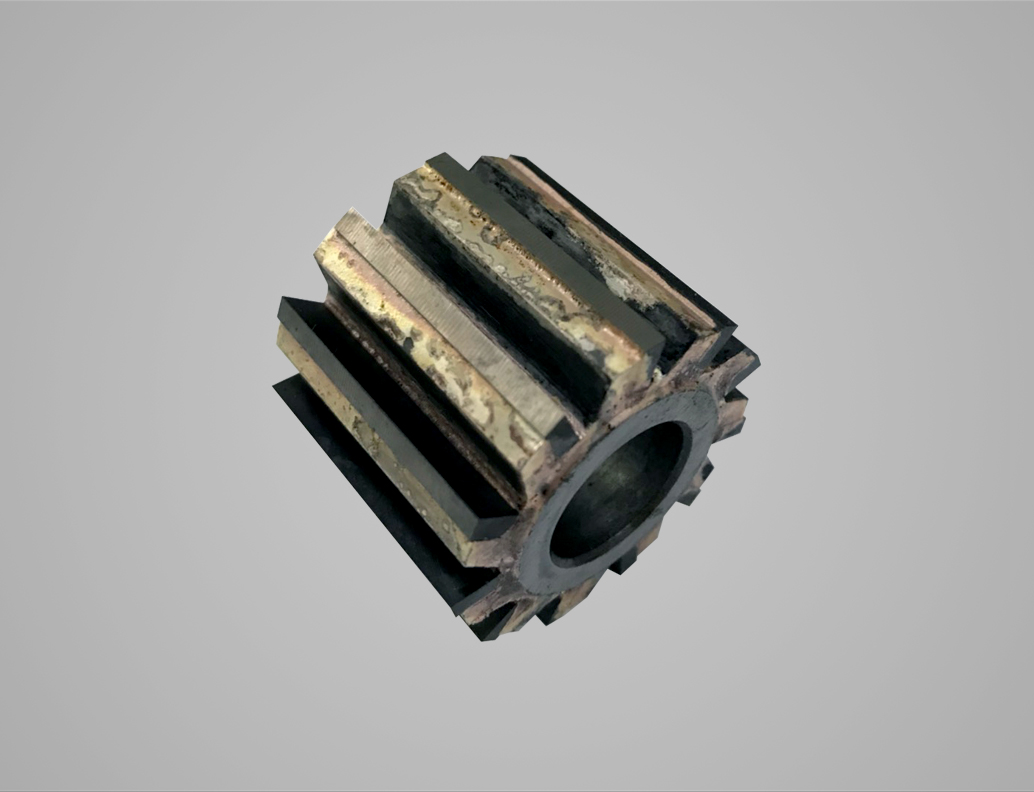

Insert

Tool Holder

PH Cutter

Torx Cutter

SL Cutter

PZ Cutter

Hex Cutter

Ball Type Cutter